1. There is no insurance on both high and low voltage s […]

1. There is no insurance on both high and low voltage sides of the distribution transformer. Although some are installed with drop fuses and horn fuses, most of toroid transformer the fuses are replaced by aluminum or copper wires, which causes the fuses to fail to blow normally. When the low voltage is short-circuited or overloaded, the transformer burns out. Improper configuration of high and low fuses in distribution transformers. Fuses on transformers are often overconfigured, which results in transformer burnout when distribution transformers are severely overloaded.

2. Due to the large number of lighting lines in rural areas, most of them use single-phase power supply, coupled with the randomness and inadequate management of jumpers in the construction process, resulting in unbalanced operation of distribution load phases. Use, cause the phase coil insulation to age and burn the transformer.

3. Tap switch

1. Unauthorized adjustment of the tap changer. The voltage varies greatly due to the huge difference in electrical load between winter and summer. As a result, some rural and enterprise electricians adjusted the tap changer without being tested and adjusted by the power maintenance and testing department, resulting in the distribution transformer being burned down due to poor contact.

2. The quality of the tap changer is poor and the structure is unreasonable. Stress is not enough. Contacts cannot be closed. The position of the outer character wheel does not exactly match the actual position of the inner. The location that causes the star to move the contacts is not fully contacted. Misaligned moving and stationary contacts reduce the insulation distance between the two taps. Under the voltage activity between the two taps, a burst discharge to ground or a short circuit occurs. Fault voltages can quickly burn out the turns of the tap, or even destroy the entire transformer.

3. oil leakage is the most common abnormal appearance of transformers. Since the transformer body is full of oil, all connection parts have rubber beads and gaskets to prevent oil leakage. After a long time of operation, some rubber beads and rubber pads in the transformer will age and crack, causing oil leakage, which will cause the transformer to be damp, short-circuited after discharge and the insulation performance of the transformer will be reduced.

4. Most of the high and low voltage lines of distribution transformers are introduced by overhead lines. Because the arrester is not put into operation in time or the 10kV arrester is not installed, the transformer is burned out during lightning strikes.

5. Some distribution transformers are not equipped with primary protection, or are equipped with primary protection, but their operability and reliability are extremely low, and some even cannot operate at all.

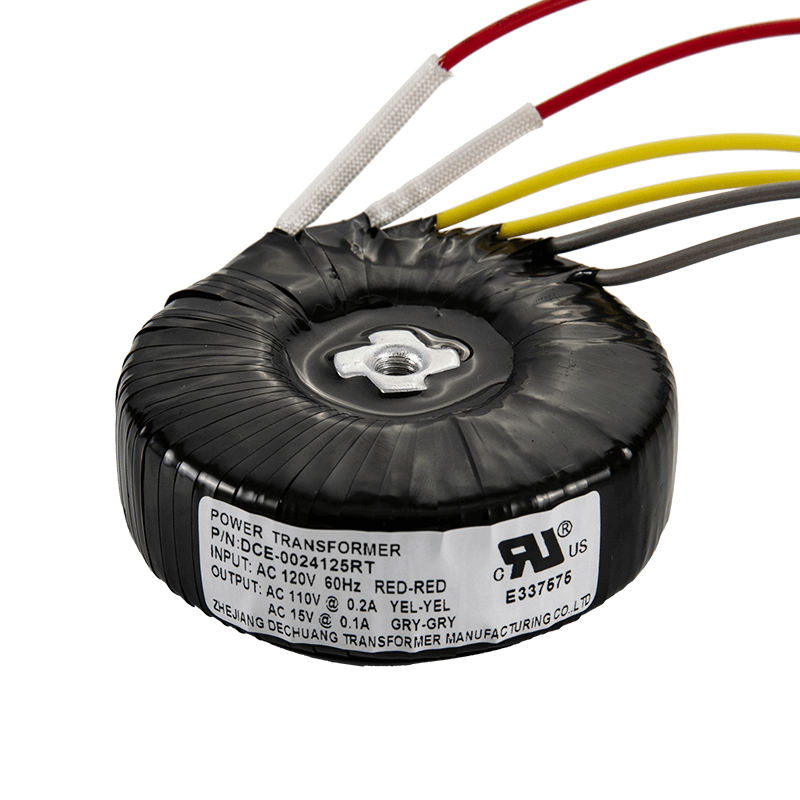

Zhejiang Dechuang Transformer Manufacturing Co., Ltd.