The most common and commonly used in life is the oil-im […]

The most common and commonly used in life is the oil-immersed transformer, which can be used indoors and outdoors, and is the most common power distribution component. Let me give you a general introduction to the components of an oil-immersed transformer.

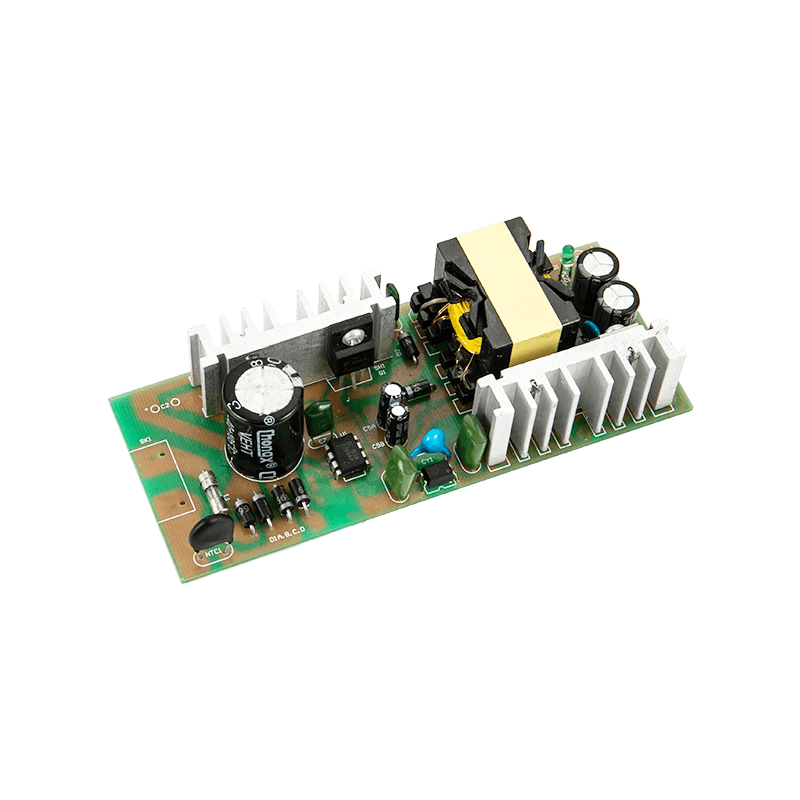

Its main structure is composed of body, oil tank, cooling device, protection device and outlet device. The body includes iron core, winding (coil), insulation, lead wire and tap switch; the fuel tank includes the fuel tank body and fuel tank accessories (drain valve, grounding screw, trolley, nameplate, etc.); cooling device includes radiator and cooler; The protection devices include oil conservator, oil indicator, safety airway, moisture absorber, temperature measuring element and gas relay; outlet devices include high and low pressure bushings.

1. Iron core: The iron core is one of the most basic components of the transformer, and it is the magnetic circuit part of the transformer. The primary and secondary windings of the transformer are on the iron core, in order to improve the magnetic circuit permeability and reduce the eddy current in the iron core. Loss, the iron core is usually made of 0.35 mm silicon steel sheet with surface insulation. The iron core is divided into two parts: an iron core column and an iron yoke. The iron core column is covered with windings, and the iron yoke connects the iron cores, and its function is to close the magnetic circuit.

2. Winding (coil): The winding is also one of the most basic parts of the transformer. It is the circuit part of the transformer, usually made of copper wire or aluminum wire wrapped in insulating paper. The windings connected to the high-voltage power grid are high-voltage windings, and the windings connected to the low-voltage power grid are low-voltage windings. The function of the winding is the carrier of current, generating magnetic flux and induced electromotive force.

3. Accessories: The accessories of the power transformer include oil tank, oil pillow, tap switch, safety air passage, insulating sleeve, etc. Its function is to ensure the safe and reliable operation of the transformer.

(1) Oil tank: The oil tank is the outer shell of an oil-immersed transformer. The iron core and windings of the transformer are placed in the oil tank, which is filled with transformer oil.

(2) Oil conservator (oil pillow): installed on the oil tank to isolate the inside of the oil tank from the outside world.

(3) Safety air passage (explosion-proof tube): Installed on the top cover of the fuel tank to protect the equipment and prevent damage to the fuel tank in case of failure. When a transformer fails and a large amount of gas is generated, the pressure in the fuel tank will increase, and the gas and oil will break through the explosion-proof membrane and spray out to prevent the fuel tank from bursting.

(4) Gas relay (Buchholz relay): It is installed in the pipeline between the transformer's oil tank and the oil conservator, and is the main protection device. Inside, there is a float with a mercury switch and a baffle that can drive the mercury switch. When the transformer fails, the generated gas gathers on the upper part of the gas relay, the oil level drops, the float sinks, and the mercury switch is turned on to send a signal; when the transformer fails seriously, the oil flow breaks through the baffle, and the baffle deflects to drive a set of mechanisms Turn on another mercury switch, send a signal and trip.

(5) Tap switch: In the power system, in order to control the output voltage of the transformer within the allowable range, the number of turns of the primary winding of the transformer is required to be adjusted within a certain range. Therefore, the primary winding is generally equipped with taps, which are called taps. Connector. Using switches to connect with different connectors can change the number of turns of the original winding to achieve the purpose of voltage regulation. The tap changer is divided into on-load tap changer and no-load tap changer.

(6) Insulating bushing: installed on the oil tank cover of the transformer, the function is to lead the coil lead end from the oil tank and insulate the lead wire from the oil tank. For voltages lower than 1KV, use porcelain insulating bushings, for voltages of 10-35KV, use gas-filled or oil-filled bushings, and for voltages above 110KV, use capacitive bushings.

(7) Transformer oil: requirements: high medium strength and low viscosity, high ignition point and low freezing point, free of impurities such as acid, alkali, dust and moisture. Role: to strengthen insulation and heat dissipation.

(8) Temperature measuring device: monitor the oil surface temperature of the transformer. Small oil-immersed transformers use mercury thermometers, and larger transformers use pressure thermometers.

Zhejiang Dechuang Transformer Manufacturing Co., Ltd.